Current News "Help Me I am Melting"

This workshop project started as a repair to a member’s locomotive but grew into more of a cautionary tale of “progress” in model railroad equipment. The issue, presented at our meeting, was the stalling of a switch engine on different sections of trackage on a number of layouts.

This Atlas loco, seen on Jack Zimmer’s Layout has full sound and lights programmed but would end up restarting in various locations on member’s layouts. The issue is relatively new for this locomotive and was frustrating to operators during operating sessions.

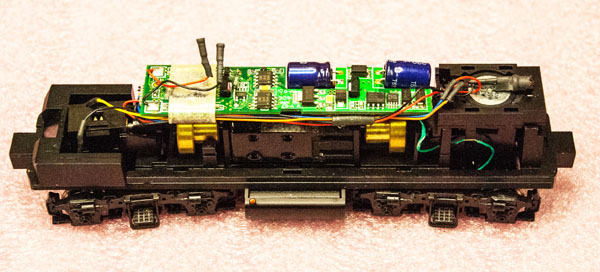

We tested this with a simple 3X5 card placed on the track to break contact for one truck. The test showed that if either truck was removed from the track the locomotive shut down. An engine that failed like this on both trucks called for an internal investigation.

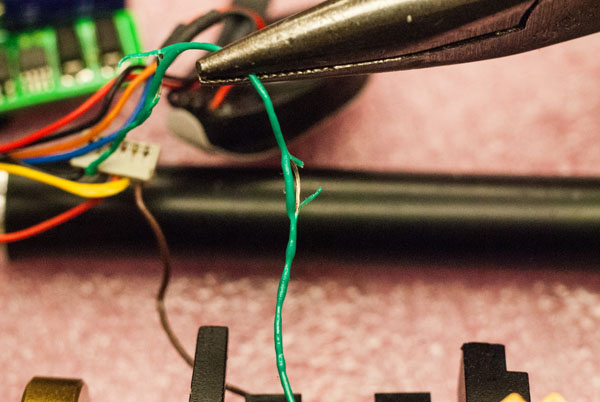

After removing the body shell we were surprised to find wires going from the front truck to the QSI decoder had melted insulation in more than one location. Upon further study we found less melting of the other wires from the trucks to the 6 pin QSI connector which brings the track power to the QSI sound board and transmits the power to the motor.

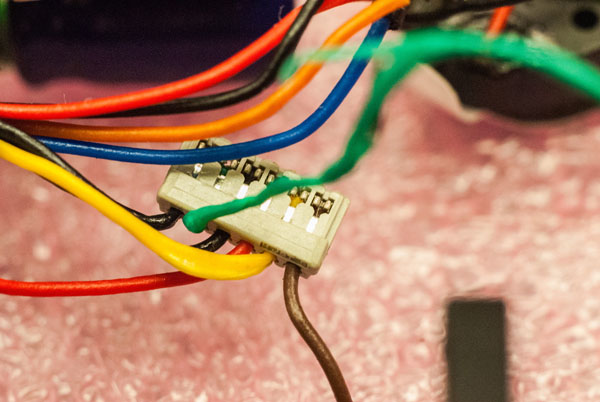

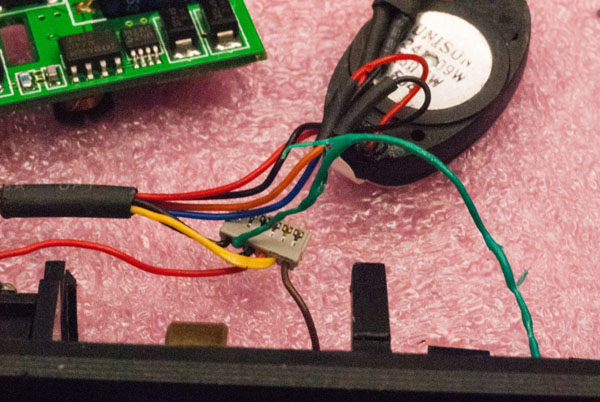

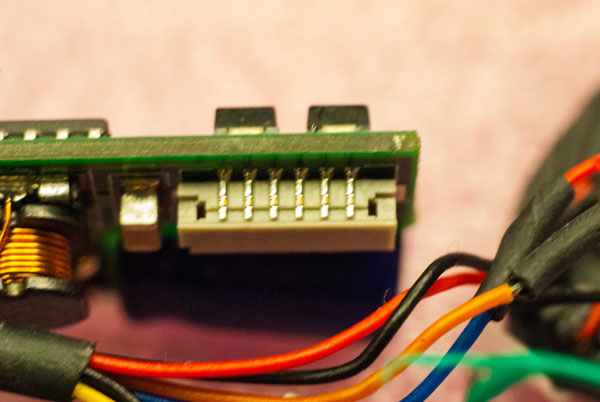

In this image you see the wires on the QSI connector do not follow the recommended practice color code. From left to right the wires are black from the engineers side (right rail) rear truck, the green wire is from the same side front truck, the next wire to the right, black, is one of two wires to the motor as is the orange wire next to it, the yellow wire is from the left rail rear truck and last the brown wire is from the left rail front truck. Normal NMRA color code would have the Red wire from the Right rail, Black from the Left rail and Gray and Orange to the motor. Melted insulation is visible on 3 of the four wires that connect the trucks to the QSI connector.

None of the melted wires were fused (burned open) however the green wire and the brown wires were intermittent in their connection with the trucks.

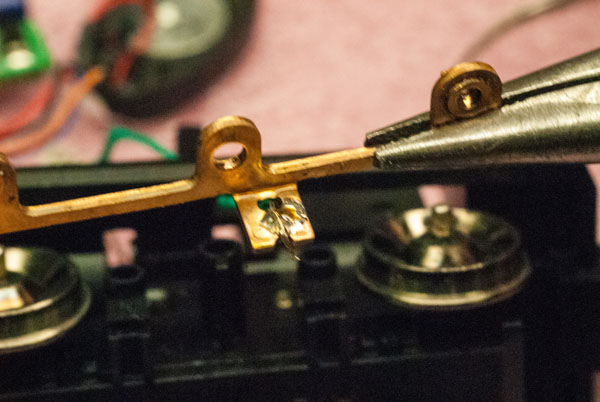

Continuity checks were made with a Simpson VOM meter using a clip lead to a #11 blade to probe the very small contacts on the QSI plug.

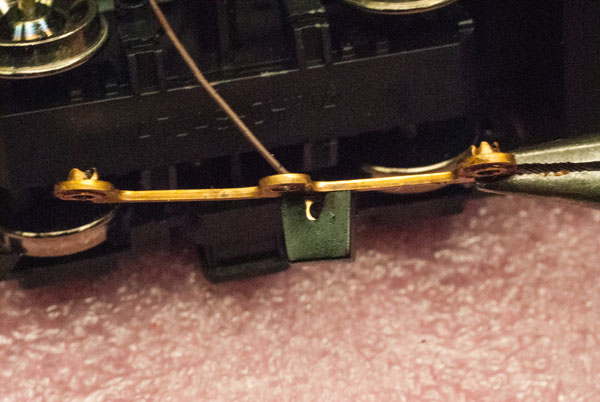

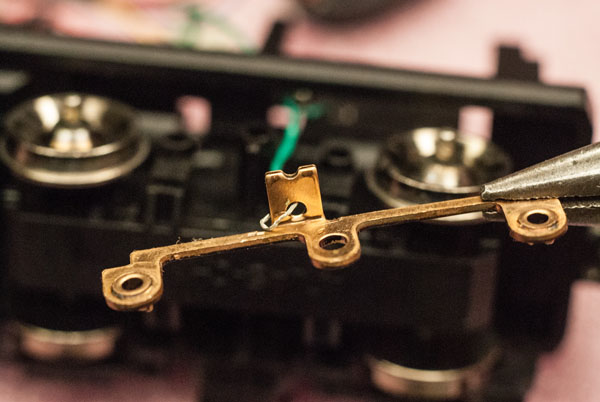

Upon opening up the truck side frames to examine the connections of these wires to the wheels we found that the wires were press fit to the bronze side frame. The wire from the decoder is held onto the side frame by plastic fittings in order to make an electrical connection. It appeared that the melting of the wire’s insulation had caused the loss of pressure in the fitting and shaking the truck would make and break the contact.

The solution was to solder the wire to the side frame. We also corrected bends in the side frames which helped hold the wheels in proper alignment.

Rather than replace the wires we cleaned the melted insulation and coated the wire with nail polish.

Care must be taken in removing the trucks and side frames as they are press fit and could easily break. Reinstalling the frames may require the help of a small drop of gap filling AC cement.

Locomotive connections were rebuilt and it now works without a problem.

This is not the end of the story as we have seen these problems on other locos brought in for repair. In the rest of this article we will address questions to ask and try to give some answers to help prevent melting of the wires and fusing of wires and traces on decoders.

Updated 10/11/14

Join us in the “Greatest Hobby” as a member of the TLMRC.